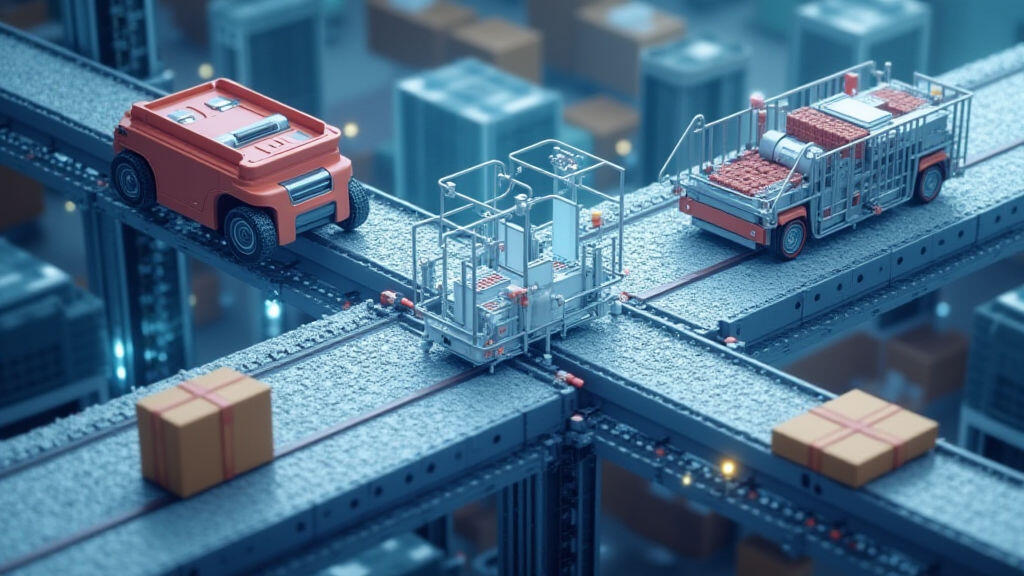

The logistics and conveying industries are undergoing a revolution driven by automation, efficiency, and the relentless pursuit of faster delivery times. At the heart of this transformation lies the reliable operation of conveyor systems, and at the core of those systems – often overlooked – are gear motors. Selecting the right gear motor isn't just a purchase; it's a strategic investment impacting operational cost, system performance, and overall efficiency. This article delves into common mistakes made by logistics and conveying enterprises when procuring gear motors and explores their critical applications, offering solutions to optimize this vital component.

Gear motors are a crucial link in many logistics and conveying processes. They combine the power of an electric motor with the speed reduction and torque amplification provided by a gear system. This allows for precise control of conveyor speed, load handling, and positioning, enabling efficient movement of goods. They are ubiquitous in applications such as:

The shift towards AI-powered logistics is amplifying the need for robust and precise gear motor performance. Predictive maintenance, enabled by sensors monitoring gear motor health, is becoming increasingly important to minimize downtime and maximize efficiency. The current focus on sustainable logistics also encourages the adoption of energy-efficient gear motors.

Despite their vital role, many logistics and conveying businesses make errors when purchasing gear motors. These mistakes can lead to performance issues, costly repairs, and decreased operational efficiency.

1. Neglecting Application-Specific Requirements: One of the most prevalent mistakes is choosing a gear motor based on general specifications without considering the specific application. Factors like load capacity, required speed, torque requirements, environmental conditions (dust, temperature, humidity), and duty cycle are all critical. For instance, a heavy-duty conveyor handling palletized goods requires a drastically different motor than one used for transporting lightweight boxes in a sorting system.

Solution: Conduct a thorough application analysis. Document the load characteristics (weight, distribution), speed and acceleration needs, operating environment, and expected lifespan. Share this detailed information with potential gear motor suppliers. Utilize online gear motor selection tools provided by manufacturers or consultants.

2. Ignoring Gear Ratio and Efficiency: The gear ratio directly impacts the output speed and torque. Choosing an inappropriate gear ratio can lead to inefficient power transmission or insufficient torque for the task. Similarly, neglecting the efficiency of the gear motor results in energy waste and increased operating costs.

Solution: Carefully calculate the required gear ratio based on the motor's speed and the desired output speed. Compare the efficiency ratings of different gear motors and select models with high efficiency (ideally over 90%). Look for gear motors with optimized gear designs (e.g., helical gears) for smoother operation and reduced noise.

3. Overlooking Motor Type and Enclosure: Different motor types (e.g., AC induction, DC, servo) cater to distinct performance needs. Choosing the wrong motor type can limit performance and increase maintenance requirements. Furthermore, the enclosure type (e.g., totally enclosed fan-cooled (TEFC), ingress protected (IP)) determines the motor's resistance to environmental factors.

Solution: Assess the specific requirements of the application and choose the motor type accordingly. For continuous operation in harsh environments, a TEFC motor is recommended. For applications requiring precise speed control, consider a servo motor. Always select an enclosure with an appropriate IP rating to protect the motor from dust, moisture, and other contaminants.

4. Failing to Verify Supplier Reputation and Support: Purchasing from a reputable supplier is vital to ensure quality, reliability, and access to technical support. Suppliers offering limited warranty, poor customer service, or lack of technical expertise can create significant problems down the road.

Solution: Research potential suppliers thoroughly. Check online reviews, request references, and assess their experience in the logistics and conveying industry. Ensure the supplier offers comprehensive technical support, including installation assistance, troubleshooting, and spare parts availability.

5. Ignoring Long-Term Maintenance Costs: Initial purchase price isn’t the only cost to consider. Gear motors require regular maintenance, including lubrication, inspection, and potential gear replacement. Neglecting maintenance can lead to premature failure and costly downtime.

Solution: Inquire about the manufacturer's recommended maintenance schedule and estimated maintenance costs. Factor these costs into the total cost of ownership when comparing different gear motor options. Consider gear motors with long-life bearings and robust gear designs to minimize maintenance requirements.

Beyond their basic function, understanding the specific application of a gear motor is critical for optimal performance. Here’s a breakdown of common use cases:

The future of gear motors in logistics is being shaped by emerging technologies like Industry 4.0, AI, and the growing emphasis on sustainability. Smart gear motors, incorporating sensors and connectivity features, are enabling predictive maintenance, remote monitoring, and optimized performance. Furthermore, there's a rising demand for energy-efficient gear motors that minimize energy consumption and reduce carbon footprint.

MES-Drive, for example, offers a range of energy-efficient gear motors with integrated monitoring capabilities. These features allow logistics and conveying companies to proactively address potential issues, optimize energy usage, and improve overall operational efficiency.

Conclusion:

Selecting the right gear motor for logistics and conveying applications is a complex process requiring careful consideration of application-specific requirements, motor characteristics, and supplier capabilities. By avoiding common mistakes and embracing innovative solutions, businesses can ensure reliable operation, minimize downtime, and optimize their overall logistics operations. As the industry increasingly adopts AI-driven solutions and embraces sustainable practices, the demand for smart and energy-efficient gear motors will continue to grow. Investing in these advancements now will position logistics and conveying enterprises for future success in a rapidly evolving marketplace.

Leave A Reply

Your email address will not be published. Required fiels are marked